Fast delivery within 5-7 business days

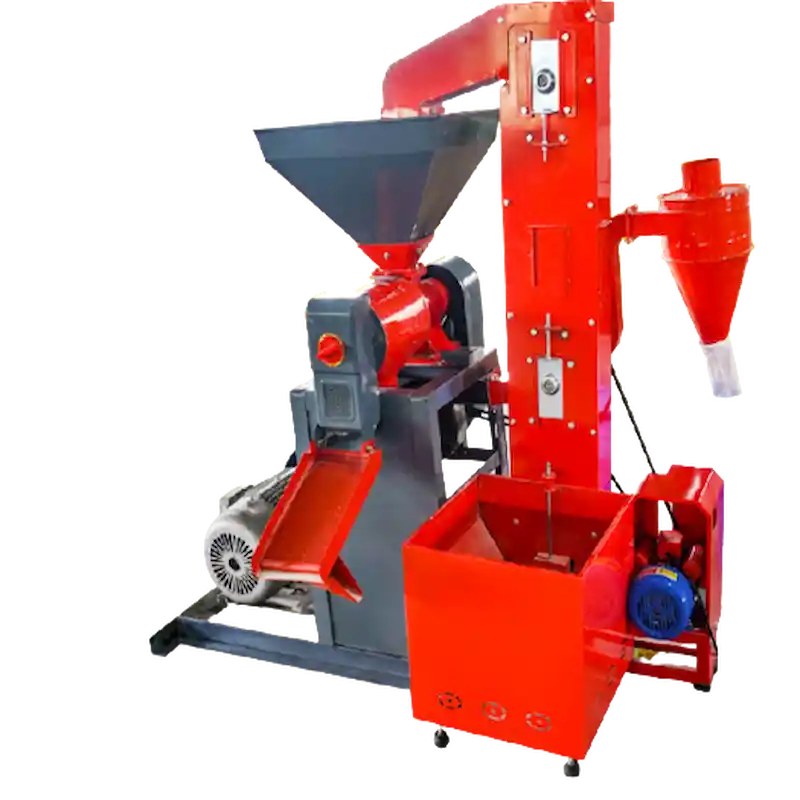

Automatic N70 PRO MAX Rice Mill With Destoner + Grader + Bucket Elevator Without Motor

₹190,000.00 Original price was: ₹190,000.00.₹137,425.00Current price is: ₹137,425.00. (Incl. of all taxes)

- Destoner+Grader+Bucket Elevator Rice Mill

- Automatic Automation Grade

- 500-700 kg/hr (approx) Capacity

Shipping & Delivery

-

Fast Dispatch

Fast Dispatch

Dispatch within 24-48 hours

1-2 Days

-

PAN India Delivery

PAN India Delivery

We offer PAN India doorstep delivery

5-7 Business Days

-

Warranty

-

Free 7 Day returns

Offers & Coupons

-

Get Flat ₹1,500 Off On Min. Purchase Of ₹50,000

Get Flat ₹1,500 Off On Min. Purchase Of ₹50,000

-

EMI Available On Min. Purchase Of ₹1,500

EMI Available On Min. Purchase Of ₹1,500

-

Save Up to 18% with GST Invoice on Every Order!

Save Up to 18% with GST Invoice on Every Order!

-

Get Flat ₹500 Off On Min. Purchase Of ₹20,000

Get Flat ₹500 Off On Min. Purchase Of ₹20,000

Specification

| Brand |

Generic |

|---|---|

| Product Type |

Rice Mill |

| Power Required |

10 HP |

| Model |

N70 PRO MAX |

| Capacity |

500-700 kg/hr |

| Motor Speed |

1440 rpm |

Description

The rice mill machine is a specialized piece of equipment used in the agricultural industry to process raw rice grains into polished rice suitable for human consumption. It plays a crucial role in modern rice milling operations, streamlining the process of removing husk, bran, and impurities from paddy rice to produce high-quality polished rice. The diverse types and features of rice mill machines cater to various scales of rice milling operations, ranging from small-scale individual farmers to large commercial rice mills. With the incorporation of automation and advanced technology, modern rice mill machines streamline the milling process, increasing efficiency and reducing manual labor. The rice mill machine offers several benefits, including waste reduction, improved yield, and enhanced uniformity in the final product. These advantages contribute to the production of clean, nutritious, and visually appealing rice, meeting the demands of consumers worldwide for this essential staple food.

Features of Rice Mill

Husking and Milling: Rice mill machines are capable of husking the paddy rice and then milling it to remove the outer layers, such as the husk, bran, and germ, resulting in polished rice ready for consumption.

Grain Sorting: Many rice mill machines are equipped with grain sorting mechanisms, such as vibrating sieves or air blowers, to separate different rice sizes and ensure uniformity in the final product.

Automation: Modern rice mill machines often incorporate automation technology, streamlining the milling process and reducing the need for manual labor. Automated controls help optimize the milling process for efficiency and consistency.

See other rice mill >> rice mill

Overview

Rice mill machines play a critical role in the post-harvest processing of rice, transforming raw paddy rice into polished rice suitable for consumption. With various types and features available, rice mill machines cater to different scales of rice milling operations, from small-scale individual farmers to large commercial rice mills. The efficiency and quality enhancements provided by rice mill machines contribute to the production of clean, nutritious, and visually appealing rice, meeting the demands of consumers worldwide for this essential staple food.

Reviews

Clear filtersThere are no reviews yet.